Mobility

Smooth, continuous and compliant product development for your specific assignment

Product development that moves

A revolution is underway in the automotive industry. The entire automotive sector is changing with the aim of making mobility more streamlined, accessible, simplified and convenient in a sustainable way. New technologies and skills are constantly required to be able to deliver the mobility products of the future.

In order for you to be able to contribute with products that create a better world, you must have partners with both extensive and broad knowledge, who can deliver the right competence at the right time and also take overall responsibility for product development. Here at Together Tech, we are far ahead.

By always working towards a better world, we help you do the same.

A growing area of knowledge

Mobility is one of our absolutely most important business areas. We constantly invest in developing our know-how, especially towards increased sustainability, and have been a significant strategic partner to the Swedish automotive industry for a long time. If you are looking for an engineering partner with a breadth of knowledge that covers all your challenges, and who quickly gets to the start of the project, then you have come to the right place. We are flexible and always use the right skills for your assignment.

Safe automation – for safety's sake

Vehicle automation is partly based on AI and deep learning and places high demands on competence. When you collaborate with us, you get help from engineers who have been involved in producing world-leading functionality in everything from Collision Avoidance to Automatic Parking. Self-driving vehicles, AD (Autonomous Drive) and driver-assisted systems (ADAS) are also high on our agenda, and attract highly competent employees internationally.

When you develop this type of product, safety is at the forefront, and in us you get a partner who works according to the industry's standards and safety classifications, for example ISO 26262. Hiring us gives you the opportunity to get high competence, fast project start and stable deliveries.

Electrification – a recharge for the future

The need and demand for electric vehicles is growing so fast that it have significant impact on the entire development chain. We are well ahead in this constantly growing field of knowledge. Electrification is of course very much about batteries, converters/inverters, energy storage and power transmission. In addition, there are also computer skills and software development. Our mobility offer is broad, very much thanks to our highly competent electronics engineers. Electrification is the future, and together with you we can make a great progress for a better world.

Infotainment – when the experience counts

As a vehicle manufacturer, you naturally want to give your customers a well-functioning and safe experience. Infotainment plays an important role there. Infotainment – for example music, media and HMI between driver and car – is a market with great development potential. We have very high competence in this area and offer high-quality and engagement.

As vehicles become more connected, we see a development towards app-like functions, something that in turn shortens lead times and increases flexibility, both in terms of your wishes and our development. We help you with competence in a number of different areas, such as connected services, sound and display systems and interaction design, to name a few.

Everything must work perfectly upon delivery. Therefore, we offer high competence in the verification of various systems, advanced function testing and testing of specific software. Everything to strengthen the experience and contribute to a safer and better vehicle world.

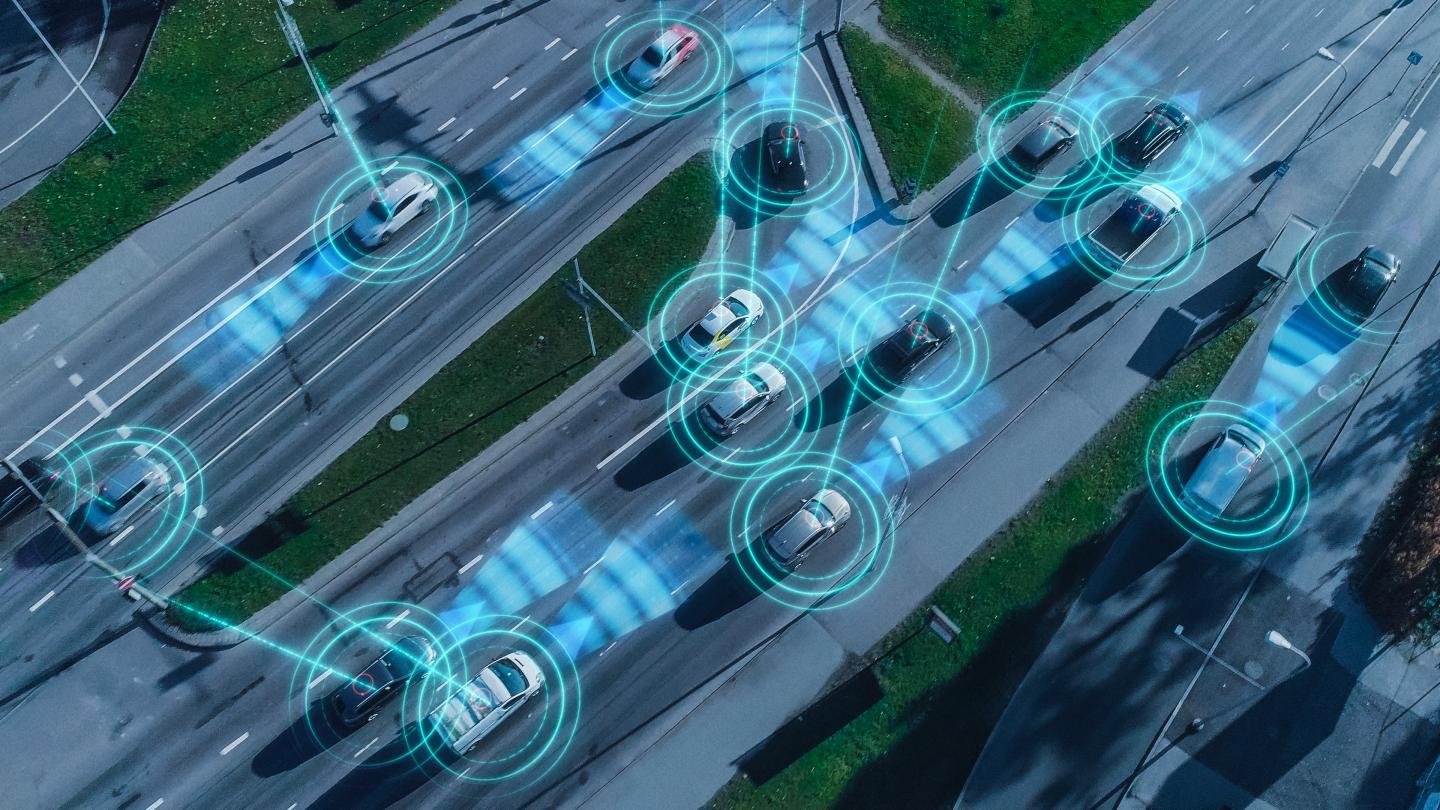

Connectivity – helps the vehicles talk to each other

Getting different vehicles to communicate with each other, connectivity, is a highly relevant area of competence in our ever more connected society. We are at the forefront in the field and strive to develop solutions that help you to streamline the relationships between the vehicles themselves, as well as to their drivers, passengers and manufacturers.

Quality & cost reduction

All assignments are unique and we are constantly faced with new challenges. It is of course crucial that you get the right skills for your particular project, and we place equal emphasis on project management, quality improvement, cost reduction, workflows and updates. In cooperation with you, we make sure to improve the ENTIRE process, so that in the end we do not only deliver an optimal product - we deliver an optimal project!

Case: Read more about a sustainably produced wheel housing - which also saves big costs!

Do you want to know more? Contact us

Related content